Expertise

We have the experience and expertise to build customised products to suit your exact requirements.

On-Site Services

On-site surveying, installation, repairs, and fabrication can effectively minimise downtime for your business.

Perfect Timing

We understand tight deadlines and strive to maintain high-quality finishes even with short notice

Australia-Wide Delivery

We ship nationwide from our Sydney warehouse, even to remote areas. We can arrange transport or work with your preferred carrier

Our Services

Service Portfolio

With over three generations of experience in plastic fabrication, we have honed our expertise to craft bespoke plastic solutions tailored to each customer’s unique needs. Our rich heritage ensures that we can bring any plastic vision to life.

Our plastic repair and installation services are carried out with utmost professionalism and attention to detail, ensuring that every project is executed flawlessly. Whether it’s repairing damaged plastic components or installing new ones, we deliver top-notch results.

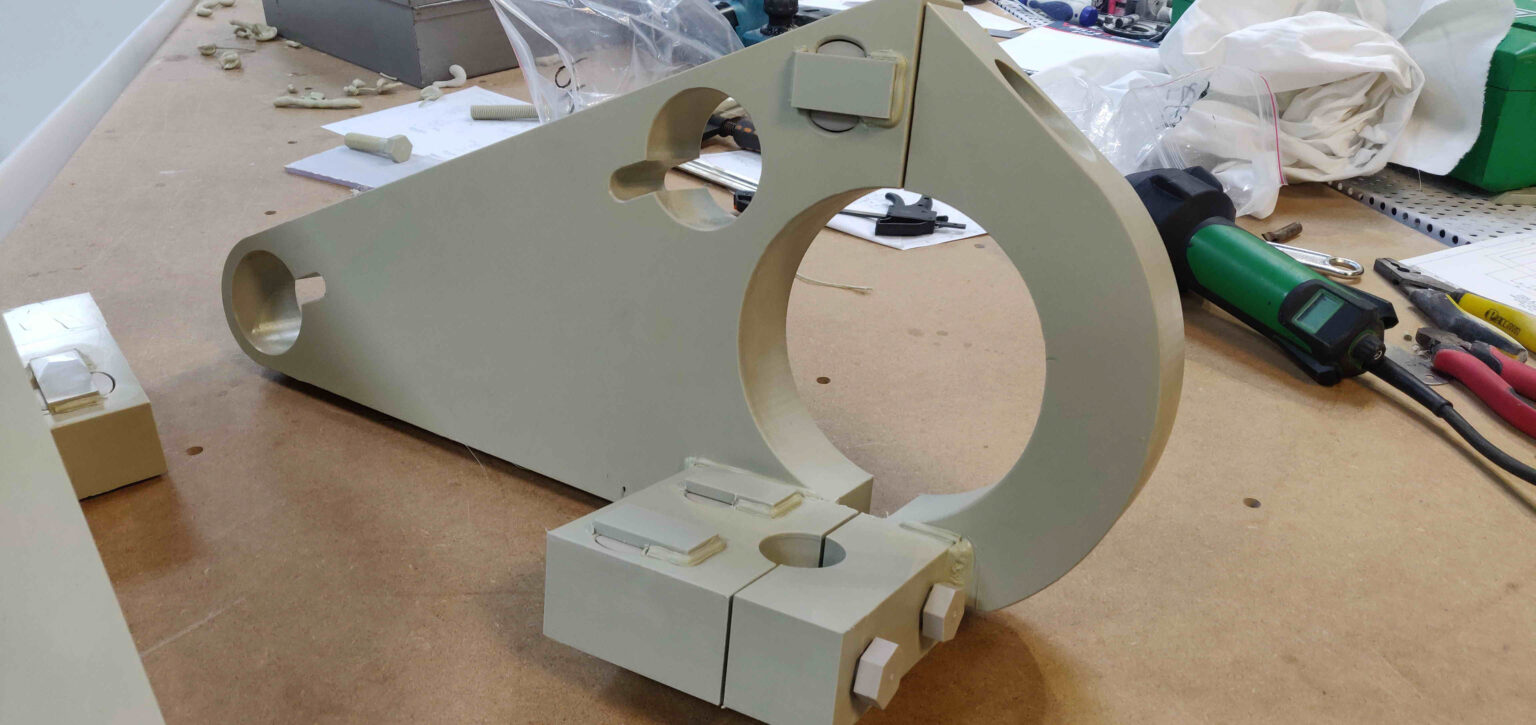

Our CNC plastic machining services utilize cutting-edge technology to intricately shape and craft plastic materials, ensuring precise, high-quality results. Whether it’s intricate designs or large-scale projects, we consistently deliver precision and efficiency in every CNC plastic machining task.

Protective barriers and enclosures made from plastic materials, designed to enhance workplace safety by preventing access to hazardous machinery, equipment, or areas.

Comprehensive process of designing, prototyping, and manufacturing plastic-based products, encompassing everything from initial concept to final market-ready items

About Us

25 Years of Manufacturing Excellence, Delivering Uncompromised Quality!

Founded in 2016, Komidore Plastics brings three generations’ worth of expertise to meet the rising demand for top-notch fabricated plastic products. Our unique approach seamlessly combines traditional fabrication techniques with cutting-edge technology, offering a premium solution within the market.

Our extensive skill set covers plastic welding, including rod and extrusion welding in materials such as PVC, HDPE, PP, PC, UHMWPE, ABS, and PE100 butt welding. We excel in line bending, capable of handling lengths up to 3000mm and thicknesses up to 20mm. Additionally, our capabilities encompass 2D and 3D CAD, FDM (3D printing), CNC machining (lathe and bed), on-site fabrication and installations (white card certified), reverse engineering, part customisation (including prototyping), and a host of other valuable skills.

Don’t hesitate to get in touch with us today to explore how we can meet your plastic needs

How we Work

Our Process

Ideation & Requirement Gathering

Collecting requirements from clients is an essential step in every project or business venture, vital for comprehending their needs and expectations.

CAD Drawings & Designs

The Computer-Aided Design (CAD) process entails crafting intricate digital models and drawings of objects and systems. This method helps identify errors and ensures that the design aligns with specified requirements.

Manufacturing / Fabrication

The manufacturing and fabrication process transforms raw materials into finished products, using various techniques. Plastic fabrication demands technical skill, precision, and creativity to achieve the client’s vision.

Testing & Quality Assurance

All products and designs crafted in our workshop undergo rigorous testing procedures, including industry-standard practices like spark and water tests to guarantee top quality.

Delivery

We securely wrap and package all our products to ensure their safety during transportation and storage.

Our Contributions

Industries We Serve!

Our Work

Recent Projects

Need Help with Easier Plastic Industrial Solutions? We Are Experts!

Reviews

EXCELLENTTrustindex verifies that the original source of the review is Google. Great guys to deal with. I didn’t think they would be this helpful for my small job. I needed it done urgently to repair a water tank for my food trailer that needed to go back on the road asap. Thanks Mags for your help.Posted onTrustindex verifies that the original source of the review is Google. I recently had the pleasure of working with Komidore Plastics, and I must say, I was thoroughly impressed with their services. From start to finish, they exhibited a level of professionalism and expertise that truly set them apart. One aspect that immediately stood out was their fast turnaround time. Despite the complexity of the project, they were able to deliver results quickly without compromising on quality. This was particularly impressive given the intricacies of plastic engineering involved. Moreover, I was highly appreciative of the expert advice provided by their team. They took the time to understand my requirements and offered valuable insights that significantly enhanced the project's outcome. Their proficiency in CAD design was evident throughout the process, resulting in designs that were both functional and aesthetically pleasing. What truly set Komidore Plastics apart was their iterative approach to the design. They were willing to listen to feedback and make adjustments as needed, ensuring that the final product met my specifications perfectly. This collaborative approach not only resulted in a superior end product but also made the entire process enjoyable and stress-free. Overall, I cannot recommend Komidore Plastics highly enough. Their combination of fast turnaround, expert advice, and dedication to excellence makes them a top choice for anyone in need of plastic engineering services.Posted onTrustindex verifies that the original source of the review is Google. Had spray chines welded to my Polycraft boat. Many thanks to Joel and Dave for the great workmanship and superb customer service.Posted onTrustindex verifies that the original source of the review is Google. A big thank you to the komidore team for designing and manufacturing our prototype on schedule. I can't speak highly enough of them.Posted onTrustindex verifies that the original source of the review is Google. Joel and team at Komidore completed a difficult installation on my deck above an outside kitchen. It is an unusual shape and others had said it couldn't be done. This has provided weather proofing of my deck area and looks beautiful. In addition they also installed perspex backing to wrought iron gates to the foyer. Both jobs required high levels of detail and workmanship. Fantastic job and a pleasure to deal with this company. . Thank you Joel

Get In Touch

Our Phone: 1300 012 379

Our Address: Unit 1, 58 Topham Rd, Smeaton Grange NSW 2567